Introduction to Purified Water Treatment

Pure water, clean water or pure water for short, is a pure, clean, do not contain impurities or bacteria in the water, in accord with hygienic standards for drinking water water as raw water, by electrodialysis method, ion exchange method, reverse osmosis, distillation and other appropriate, processing method, the seal in the container, and do not contain any additives, colorless, transparent, can be directly drinkable. The space water that sells on the market, distilled water belongs to pure water. Sometimes the word is also used with distilled water or rainwater from a chemical laboratory.

Metal Indicators

The metal element index stipulates the content of lead, arsenic and copper in the standard, and lead and arsenic shall not exceed 0.1mg/L, which mainly comes from the environment affected by human activities, including soil and river pollution. As lead, arsenic is poisonous and harmful elements, but by respiratory or digestive tract into the body and accumulation in the body, the lead content in the blood is 0.6 ~ 0.8 mg/L can damage the internal organs, and arsenic compounds will cause poisoning, so their levels should be as small as possible, and copper in the standard stipulated in the must not exceed 1.0 mg/L, while copper is not harmful elements, but it is not the more the better material, for pure water, one of the symbols of is to measure the degree of purity.

Organic Index

The organic index is mainly embodied in the national standard for the chloroform and carbon tetrachloride content of the provisions. Because the quality problem of barreled pure water is mainly concentrated on microorganism detection exceeding the standard, in order to solve this problem, many manufacturers are not from the production process, quality management, but only through the quantity to try to solve the problem of microorganism pollution of pure water, commonly used disinfectant for chlorine disinfectant such as chlorine dioxide. Barreled pure water can produce some new organic halogenates due to chlorination disinfection, the main components are trichloromethane (chloroform) and carbon tetrachloride and a small amount of monochloromethane, monobromodichloromethane, dibromodichloromethane and bromoform, etc., collectively known as halogenated alkyl. After detection, the halogenated alkanes content in the chlorinated drinking water and tap water is generally higher than that in the source water. Among them, chloroform and carbon tetrachloride are of high content, which is harmful to human body. If drinking chloroform and carbon tetrachloride for a long time, the purified water exceeding the standard will lead to liver poisoning or even canceration. In order to protect the health of consumers, the national standard gb17324-1998 clearly stipulates that the content of trichloromethane and carbon tetrachloride in drinking pure water shall not exceed 0.02mg/L and 0.001mg/L respectively.

Biological Indicator

In the national standards, the microbial indexes include the total number of colonies, coliform bacteria, pathogenic bacteria, molds and yeasts. From the detection of purified water in recent years, microbial indicators are one of the indicators that are easy to exceed the standard. This is due to microbial contamination in the production, processing, transportation and marketing of purified water. In production and processing, workers do not pay attention to personal hygiene, recycling bottles cleaning, disinfection is not strict, and even some manufacturers in order to reduce costs, recycling caps used again, due to the deformation of recycling caps, caused by the bottle mouth is not sealed may cause microbial pollution. The excess of microorganisms reflects the degree of water pollution. Among them escherichia coli achieves certain index, can cause human body diarrhoea. Pathogens include salmonella, shigella, staphylococcus aureus and streptococcus b. Salmonella, shigella contaminated water can cause acute intestinal infections, diarrhea, fever and other symptoms; The enterotoxin produced by staphylococcus aureus can cause poisoning, acute gastrointestinal symptoms and even life threatening. Streptococcus b is the main pathogen causing suppurative inflammation in human body. Mold and yeast widely distributed in nature, in the process of the growth of mold in the breeding in food absorb nutrients to the food in the food nutrition value is reduced, and odor, influence the sense of food, especially mould to grow in the process of producing toxins can cause chronic poisoning, severe cases can lead to cancer.

The content of nitrite is another important indicator in the national standard health index. Nitrite mainly comes from the nitrate in the soil near the water source, and the nitrate content is higher in the saline-alkali land, the nitrate fertilizer applied in large quantities and the soil short of molybdenum. Nitrite shall not exceed 0.002mg/L in the national standard.

The Production Mechanism

In the production process of high purity water, anions and cations in water can be removed by electrodialysis, reverse osmosis and ion exchange resin technology. In general, the particles in water can be removed by ultrafiltration, membrane filtration and other technologies. Bacteria in water, at present, the domestic use of medicine or ultraviolet lamp irradiation or ozone sterilization method to remove; Water TOC is generally activated carbon, reverse osmosis treatment. In the field of high pure water application, the purity of water is directly related to the performance, reliability and threshold voltage of devices, leading to low breakdown, defects, and affecting the few children life of materials. Therefore, high pure water requires high purity and precision.

Natural dissolved gases in water mainly include O2, CO2, SO2 and a small amount of CH4, radon and chlorine. In the production process of high purity water, it is also necessary to remove such gases. In order to effectively remove impurities, some chemical fungicides, such as formaldehyde, hydrogen peroxide and sodium hypochlorite, were added in the process of producing high purity water. These are some of the reasons why high purity water is not drinkable.

So what is pure water? Pure water refers to the water quality pure, does not contain any harmful substances and bacteria, such as organic pollutants, inorganic salt, any additives and various impurities, effectively avoid the invasion of the human body all kinds of germs, its advantage is that can be safely effectively supplement moisture to the body, strong solubility, strong affinity to the human body cells, therefore, it can promote metabolism.

It is water produced after deep treatment by ion exchange, reverse osmosis, fine filtration and other appropriate physical processing methods. Under normal circumstances, in the production process of pure water, only 50% to 75% of the source water is used, that is to say, 1 kg of tap water or groundwater can only produce about 0.4 kg of pure water, and the remaining 0.6 kg of water cannot be used as drinking water, can only be used for other purposes.

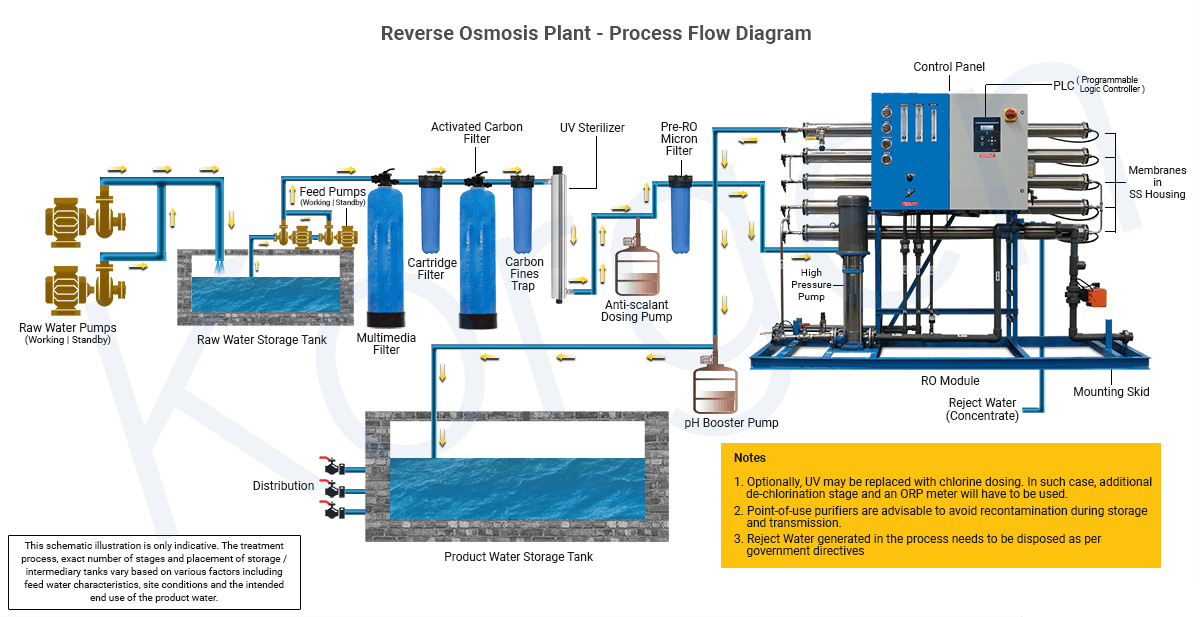

RO System Design, Construction and Commissioning

1) Design

Determine the pretreatment process and its effect, mainly to confirm the water quality index after pretreatment. The reverse osmosis feed water or system inlet water we talk about is the water quality after pretreatment.

2) Implementation of Design Basis

Raw water quality and raw water type, specific water quality indicators of water production. When getting raw water quality data, be sure to confirm the type of water source, possible water quality fluctuation range, water intake method and the possibility of secondary contamination. In surface water treatment and seawater desalination projects, the way of water intake is also the most critical in the design of the whole system. It is necessary to implement the quality data of discharged water repeatedly in the sewage reuse and treatment project, and transform the sewage treatment system when necessary to ensure the feasibility of reverse osmosis process.

3) Selection of Membrane Components

According to the salt content of raw water, the condition of water quality and the requirement of water quality, select the appropriate membrane element. Please refer to the design guide of the preamble and the topographic map of the guide for the selection of membrane components.

4) Determine Membrane Flux and System Recovery

The type of RO membrane element and the water flux per unit area (GFD or L/m2h) and recovery rate are determined according to the different requirements of inlet water quality and treatment water index. The water yield flux can be referred to the design guidelines of hynder energy. The setting of recovery rate should consider the precipitation limit value (saturation index) of insoluble salt contained in raw water, the type of feed water quality and the water quality. Generally, the design of water yield J and recovery R per unit area is too high, and the possibility of membrane pollution is greatly increased, resulting in a decrease in water yield, an increase in the frequency of cleaning the membrane system, and an increase in the cost of maintaining the normal operation of the system. Therefore, in the design of the system, under possible conditions, the design water flux and recovery rate are expected to be wide.

5) Permutations and Series

We will design the appropriate membrane number and arrangement according to the field needs and relevant calculations.

6) Optimal Design

According to the set water flux J per unit area, the recovery rate, and the range of water temperature variation, the arrangement mode of the membrane module was studied and discussed, and the pressure and flow were designed and calculated. At this time, the RO design component (IMSdesign) provided by hynen company can be very convenient to help customers complete this key task.

According to the required water yield Qp, the number of membrane elements (Ne) required to meet the water yield requirement is calculated on the basis of the type of water source and the film pollution compliance factor. Estimated number of pressure vessels (Nv) and system arrangement based on recovery rate. The above conditions are input into the design elements, and through various arrangement calculation, the inlet operating pressure and water quality can be obtained. At the same time, the performance of the membrane elements in each section can be obtained, and the optimal combination can be selected.

The Construction of the Plant

Our company will send professional and technical personnel to guide and install on site according to the designed scheme.

Debugging

The installed equipment will be debugged scientifically, and technical communication and explanation will be given to customers to ensure the normal operation.